Ducting and low pressure expansion joints are lightweight flexible connectors designed for gaseous media made out of natural or synthetic elastomers, with combinations of rubber and fabric reinforcement especially for scrubbers, precipitators, baghouses, and fans in air handling systems. Ducting expansion joints will help solve problems such as:

- Stresses - expansion joints absorb movement due to thermal expansion and contraction of ducting

- Misalignment - the lightweight and highly flexible nature of the expansion joints installs easily and compensates for installation tolerances in duct alignment, or for movement and settling over time

- Noise - transmission of sound is reduced as the expansion joint acts as a dampener and absorbs the noise levels

- Vibration - rubber expansion joints significantly reduce vibration when installed in proper locations and are not subject to metal fatigue failure

Similar low pressure expansion joints are often found in gravity fed applications in the connections of hoppers, silos, shaker tables, vibratory conveyors, and bowl feeders where large amounts of movement with minimal resistance is required. High quality, premium connectors in these applications help improve process efficiency by reducing material loss, foreign contamination, and replacement frequency. The flanged and sleeve connectors allow for easily installation and improve airborne and physical hazards associated with media leaking outside of these processes. Low pressure expansion joints also help solve problems such as:

- Abrasion - with proprietary elastomers such as ABRA-LINE, abrasion can be significantly reduced compared to other rubber or metallic connectors

- Corrosion - no metal to metal contact eliminating electrolysis between dissimilar metals

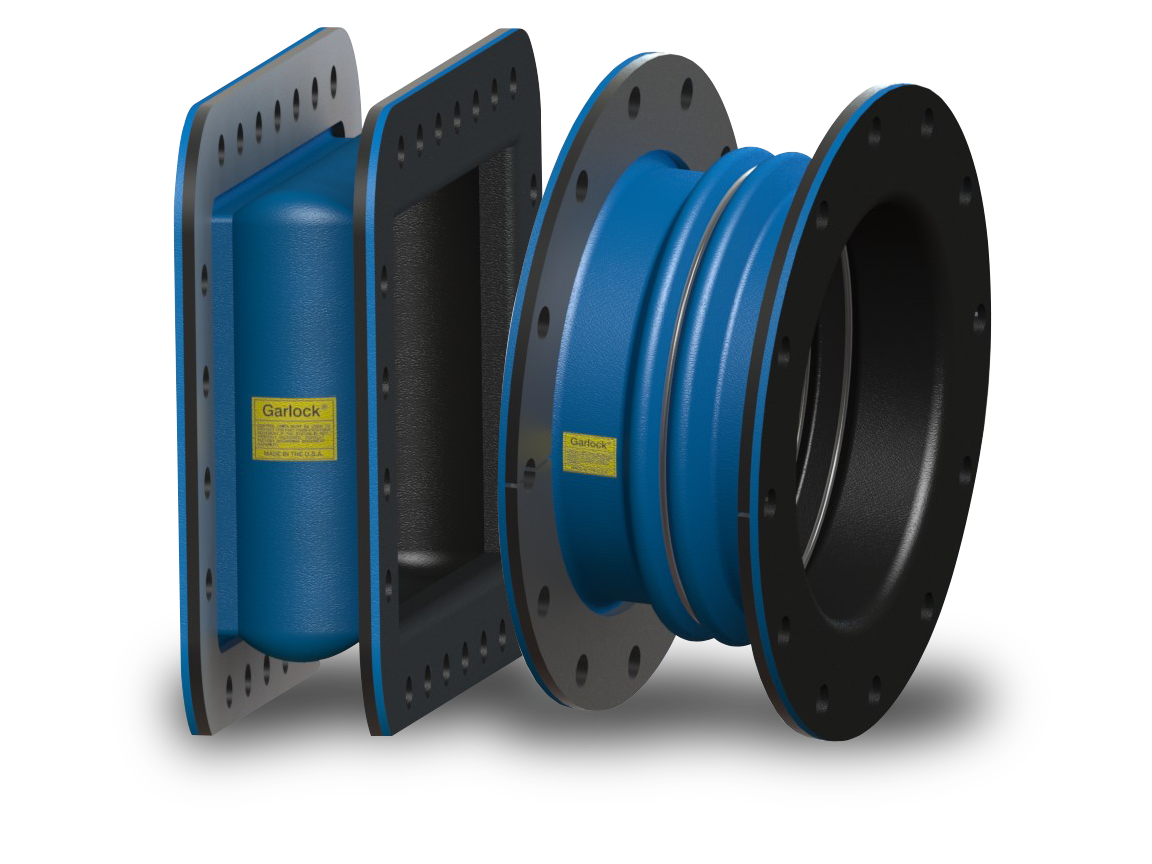

Optional metal reinforcement in Style 9394 Expansion Joints allow for a high level of flexibility and movement along with greater pressure and vacuum capabilities typically found in standard ducting expansion joints.

For more information, please see our EJ Materials Guide.

For small gap openings in power generation applications requiring internal flange connection.

For small gap openings in power generation applications requiring external flange connection.