Garlock® GYLON® gasketing is a family of severe service PTFE gasketing materials manufactured using a proprietary process that imparts unique physical properties that are not obtainable through conventional manufacturing methods.

The innovative GYLON® manufacturing process reorients the PTFE and fillers in a way that increases the material’s tensile properties and decreases the creep relaxation problems that usually plague PTFE products. In addition, the mixing process creates a homogenous material with consistent, superior physical properties that, unlike inferior skived PTFE sheet gaskets, do not fluctuate from one side of the sheet to another. Plus, our patented thermal bonding process allows us to fabricate gaskets of nearly any size.

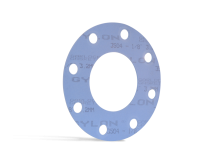

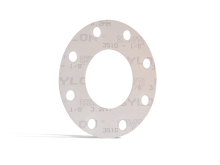

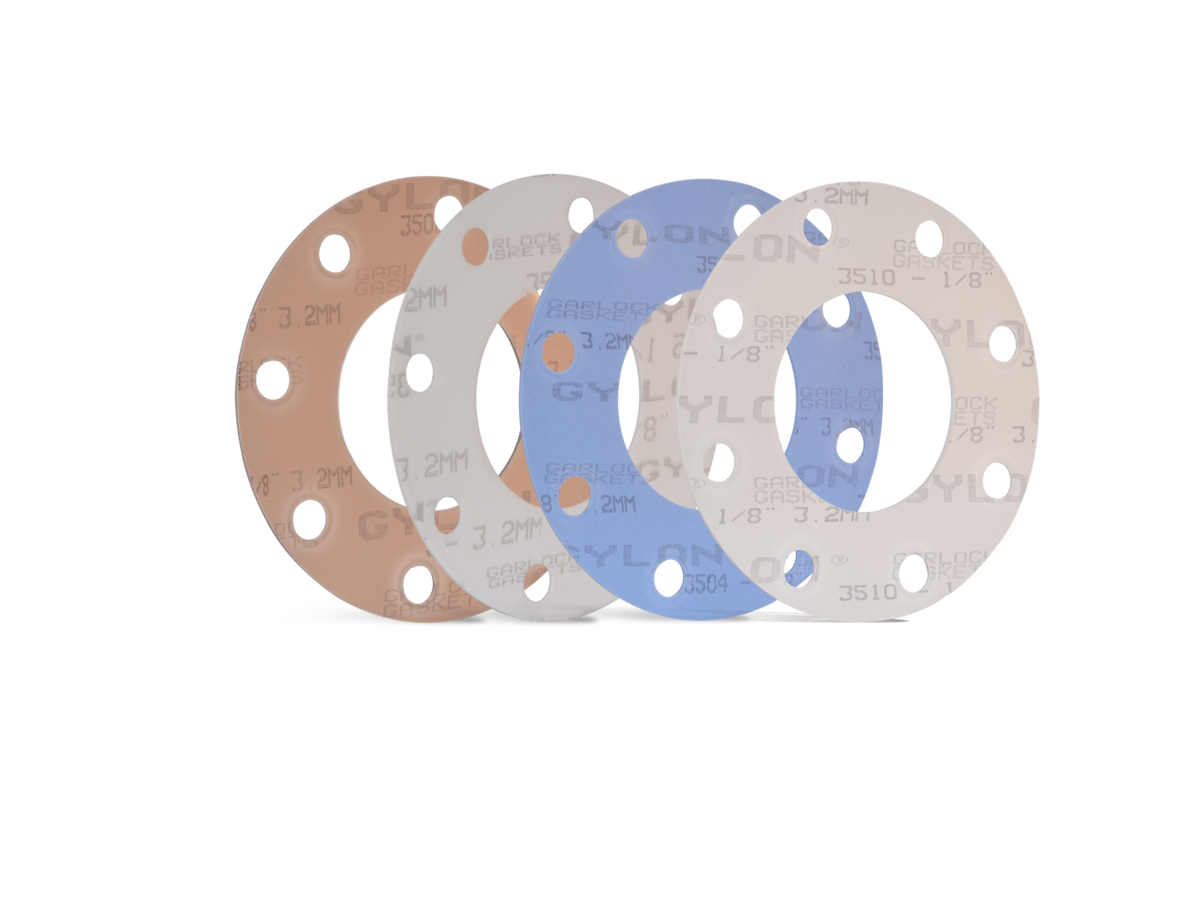

Designed for severe chemical service, GYLON® gaskets are color-coded for easy identification and provide superior sealability to reduce process and media loss and fugitive emissions. They also reduce creep and cold flow characteristics.

Also, see our new line of GYLON EPIX™ Gasketing - The Next Generation in PTFE Gaskets

For use with strong acids, solvents, hydrocarbons, and other aggressive media

For use in many acids, some caustics, hydrocarbons, refrigerants, and more

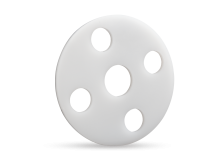

NSF 61-approved for use in oxygen service and potable drinking water.

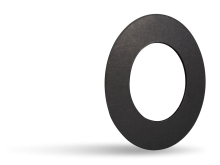

For use in strong caustics and toxic chemicals where an extremely tight seal is critical.

Can withstand high concentrations of hydrofluoric acid and volatile hazardous air pollutants

The GYLON® Style 3522 gasket is made of 100% pure PTFE with no fillers or additives, making the material ideal for the most demanding, high purity...

Suitable for flanges that generate lower compressive stresses

Tight seal on glass-lined and wavy flanges. High performance, aluminosilicate microsphere filled PTFE

Gasketing for High Pressure Applications up to 2,500 PSI

Perforated 316L stainless steel insert for improved pressure resistance up to 2,500 PSI. PTFE with Barium Sulfate Gasketing

First choice for strong acids, solvents, hydrocarbons, and other aggressive media.

Can withstand a wide range of chemicals and meets FDA regulations