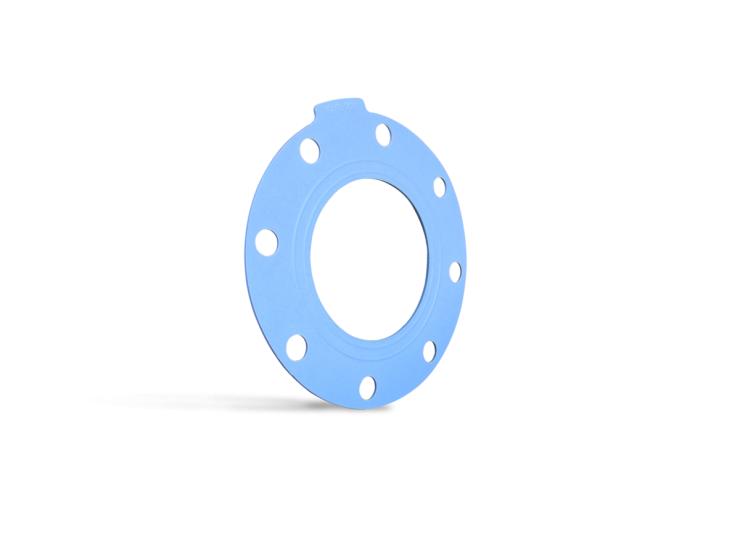

100% GYLON® PTFE with aluminosilicate microspheres

GYLON® STRESS SAVER® 3504 combines the proven sealing advantages of molded, raised ribs with the performance characteristics of the industry recognized GYLON® 3504 PTFE gasketing material. The combination of these two time-tested configurations make Style 3504 GYLON® STRESS SAVER® the ultimate sealing solution.

FEATURES and BENEFITS

- Versatility - Suitable for both metallic and non-metallic piping with either flat or raised face flanges

- Chemical resistance – GYLON® 3504 is ideal for a wide range of caustics and acids, helping to simplify the selection process

- Limited Creep and Cold-Flow – Greatly reduces the leakage after installation and system cycling

- Superior Physical Properties – Higher temperature and pressure capabilities as compared to rubber gaskets

- Homogeneous Construction – Single piece design helps avoid permeation, delamination, fold-over of PTFE envelopes and potential splitting when installed against raised face flanges

- High purity – FDA, USP Class VI, and NSF-61*

*Style 3505 GYLON® Stress Saver® is able to meet the stringent requirements of NSF-61 for potable water applications.

SPECIFICATIONS

- Composition 100% GYLON® PTFE with aluminosilicate microspheres

- Color Blue

- Temperature -450° F to 500° F / -268° C to 260°C

- Pressure PSIG 800 PSIG 55 Bar

- PxT (max) 250,000 (psig x °F) / 8,600 (bar x °C)

- Media All solvents, most caustics and acids, hydrocarbons, refrigerants, cryogenics and potable water

- Approved to NSF-61 for potable water applications.

APPLICATIONS

Industries

- Chemical Processing

- Electronics, semiconductor

- Food

- Pharmaceutical

- Pulp and Paper

- Potable/Drinking water*

Flange Types

- PVC

- FRP

- PVDF

- CPVC

- Polypropylene

- Cast and ductile iron

*Specify Style 3505 GYLON® Stress Saver®

ADDITIONAL INFORMATION

Meets ABS (American Bureau of Shipping), FDA (Food and Drug Administration), and USP (US Pharmacopeia) specifications.