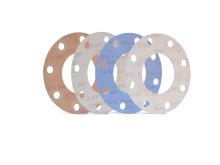

Garlock® gasketing is offered in a wide range of materials, including GYLON® restructured PTFE, compressed fiber gasketing, GRAPH-LOCK® flexible graphite sheet, THERMa-PUR Extreme Temperature gasketing and high performance rubber sheet products.

GYLON® is a time-tested proven product that is known throughout industry as the material of choice for severe chemical services. In addition, GYLON® gasket size availability is virtually limitless, as the product can be thermally bonded using a patented process.

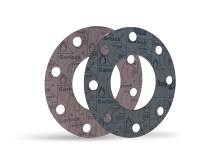

Garlock’s compressed fiber gasketing materials are manufactured using a proven technique referred to as the High Pressure Sheet (HPS) process. One thing that makes the Garlock product different from other HPS products is the way they are made using a proprietary non-VOC solvent which is environmentally friendly.

GYLON EPIX® is a newly developed family of PTFE gaskets - patented, profiled surface for optimum sealing performance.

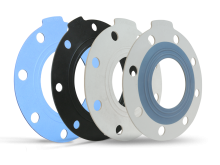

The Garlock® STRESS SAVER® family of products feature molded, raised ribs that help to create a tighter seal by concentrating the compressive load...

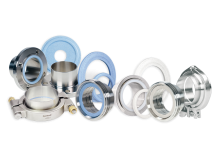

Process and equipment reliability for all pharmaceutical and food processing applications

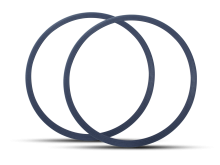

The only true “controlled swell sheet” available on the market today.

Withstands high temperatures, high pressures, and aggressive chemicals. Proven fire safe

Excels in the harshest conditions—intense heat, high pressure, saturated steam and hot oils. Laboratory tested for fire safety. Cut and sheet...

Excellent thermal stability,oxidation resistance, reduced creep relaxation and improved torque retention

Low cost gaskets that utilize vegetable fiber for low pressure, low temperature applications.

Excellent sealability,thermal stability for utility and general service applications. Compressed non-asbestos (CNA) fiber sheet