Low Pressure Applications Rubber Expansion Joint

This multi-convoluted, lightweight expansion joint is designed for low pressure applications that require significant amounts of movement, axially and/or laterally. Its low spring rates make it ideal for air handling, load cell, bin activators, vibrating bins, silos, and pellet/dough hopper applications.

Regional Availability Restrictions:

Not available in Europe

FEATURES and BENEFITS

- Lightweight design installs easily and costs less to ship

- Can be custom-designed for even greater movement capability

- Choice of construction materials suitable for wide range of temperatures

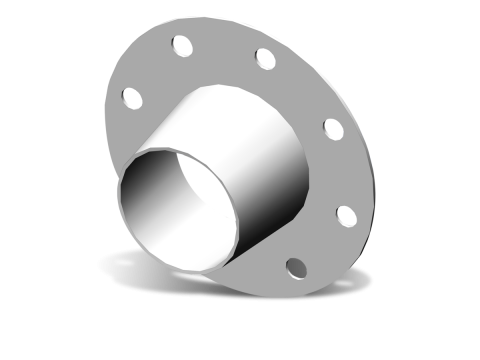

- Available in flanged or sleeve type design, up to 48in / 1219 mm ID

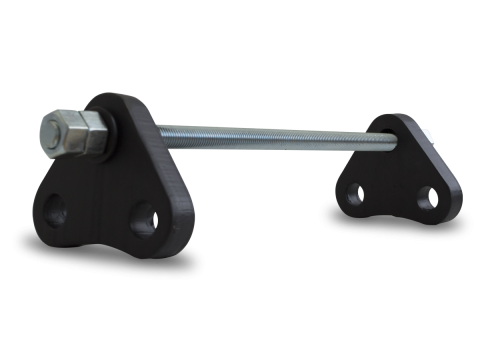

NOTE: Flanged designs require retaining rings for an effective seal. Sleeve type requires clamps; the overall length of the expansion joint should include an additional 4in / 101.6 mm for clamping space.

SPECIFICATIONS

Pressure

- Without external reinforcing rings: up to 3 psi / 0.2 bar

- With external reinforcing rings: up to 15 psi / 1.0 bar

Vacuum

- Without internal reinforcing rings: up to 3 in Hg / 75 mm Hg

- With internal reinforcing rings: up to 15 in Hg / 381 mm Hg

- Contact Garlock if higher vacuum or pressure ratings are required

APPLICATIONS

- Air handling

- Load cell

- Bin activators

- Vibrating bins

- Silos

- Pellet/dough hoppers

LINER MATERIALS

For more info on these materials click here.

- ABRA-LINE™: +180°F (+80°C)

- ABRA-SHIELD®: +300°F (+150°C)

- Natural Rubber: +180°F (+80°C)

- GUARDIAN® FEP: +400°F (+205°C)

- FKM (Fluoroelastomer): +400°F (+205°C)

- CSM: +250°F (+120°C)

- SURE-TEC™ FDA EPDM +250°F (+120°C)

- EPDM/FDA EPDM: +300°F (+150°C)

- HNBR (Hydrogenated Nitrile): +300°F (+150°C)

- Nitrile/DETECTOMER® FDA Nitrile: +250°F (+120°C)

- Chlorobutyl (Standard): +250°F (+120°C)

- Neoprene/FDA Neoprene: +250°F (+120°C)

ADDITIONAL INFORMATION

Movement Capabilities

- 3/4in / 19 mm axial compression per convolution

- 5/8in / 16 mm axial elongation per convolution

- 5/8in / 16 mm lateral deflection per convolution

- Movements are non-concurrent. Larger convolutions are available to provide more movement. Contact Garlock if above listed movements need to be exceeded.