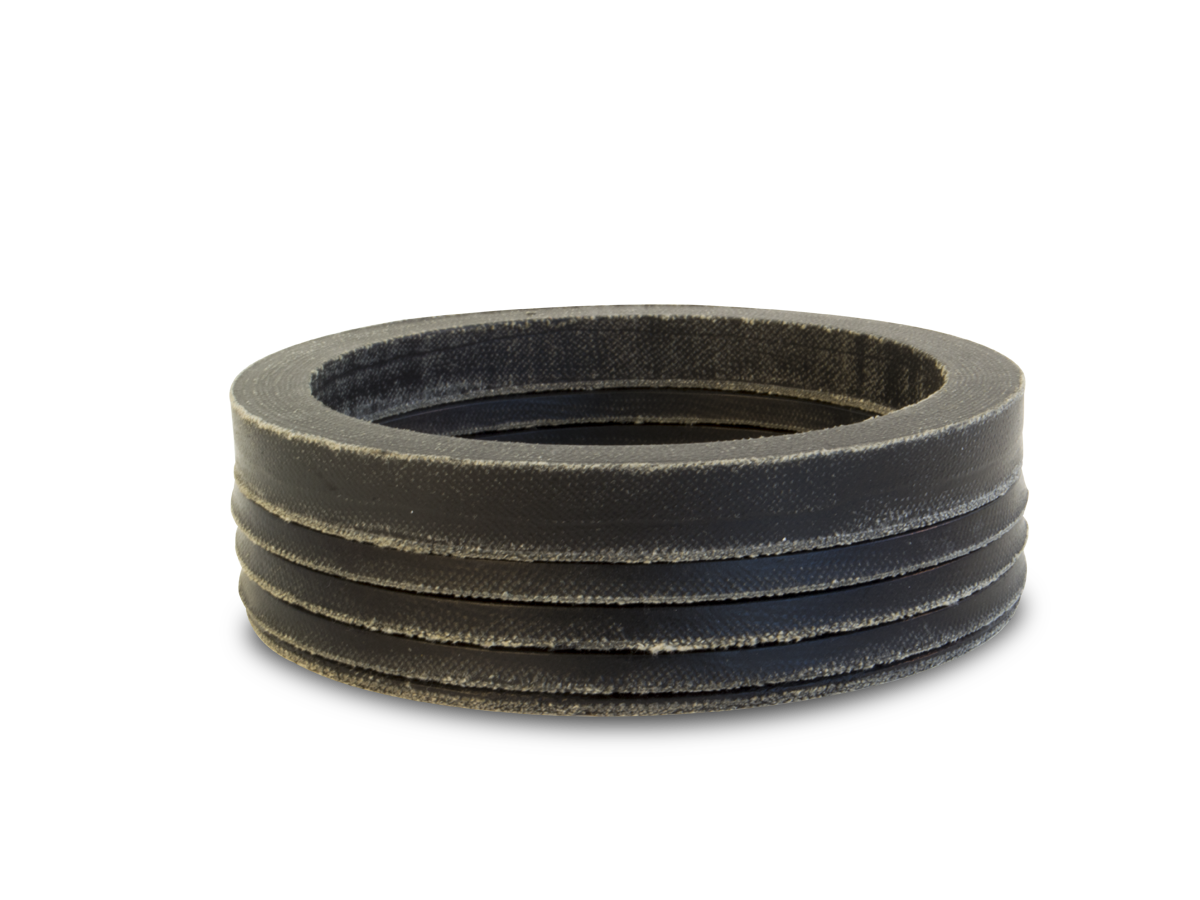

In unusually high-pressure applications, CHEVRON® packing might need to be reinforced to prevent undue distortion from this extreme pressure. The following are examples of some design considerations that can be used to overcome problems experienced with standard components (such as 432, 433, etc.).

When pressure ranges exceed those normally satisfied with standard Style 432, 433 or 532 adapters, the stronger rockhard adapters such as 260RH, 261RH, and 7857RH should be considered.

When a problem relates to excessive clearances, a close tolerance phenolic (Style 155) or bronze bushing installed behind the female adapter will act as additional support and reduce the extrusion gap. A phenolic or bronze female adapter will serve the same purpose.

These configurations have been used successfully to extend the life of CHEVRON® packing sets. However, specific applications should be considered on an individual basis, taking into account the type of equipment, size, temperature, media being sealed, pressure, surface speed, condition of equipment, and any other contributing factors.

For straight phosphate-ester fluids having no oil or hydrocarbon additives.