SURE-LINK™ PTFE Expansion Joints are available in multiple configurations commonly referred to as:

Couplings: Two convolution connectors designed for minimum movements.

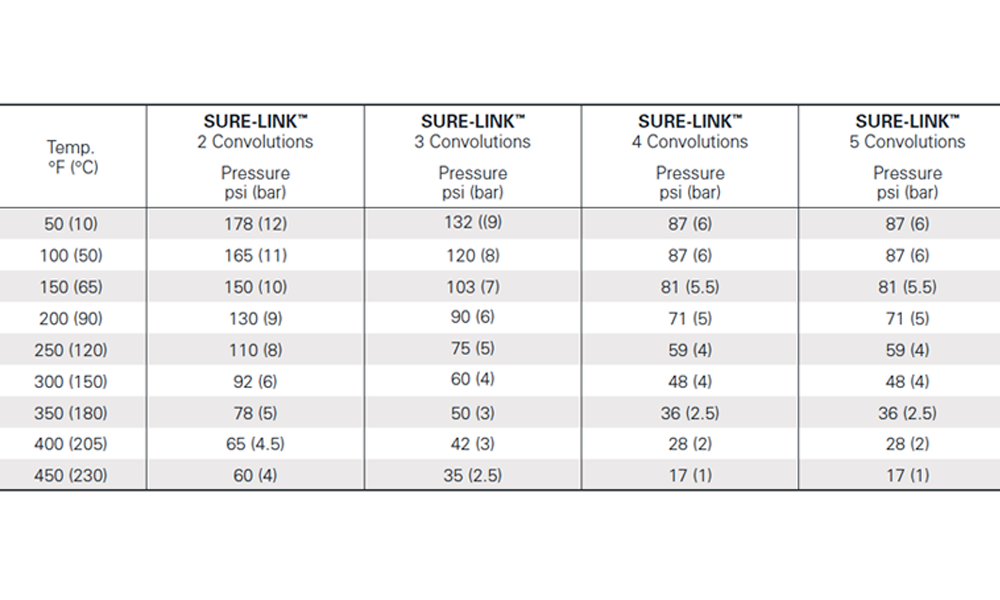

- Pressure: to 178 psig (12 bar)

- Full Vacuum: to +350°F (+180°C)

Expansion Joints: Three convolution connectors designed for easy movement and ease of system installation.

- Pressure to 132 psig (9 bar)

- Full Vacuum to +180°F

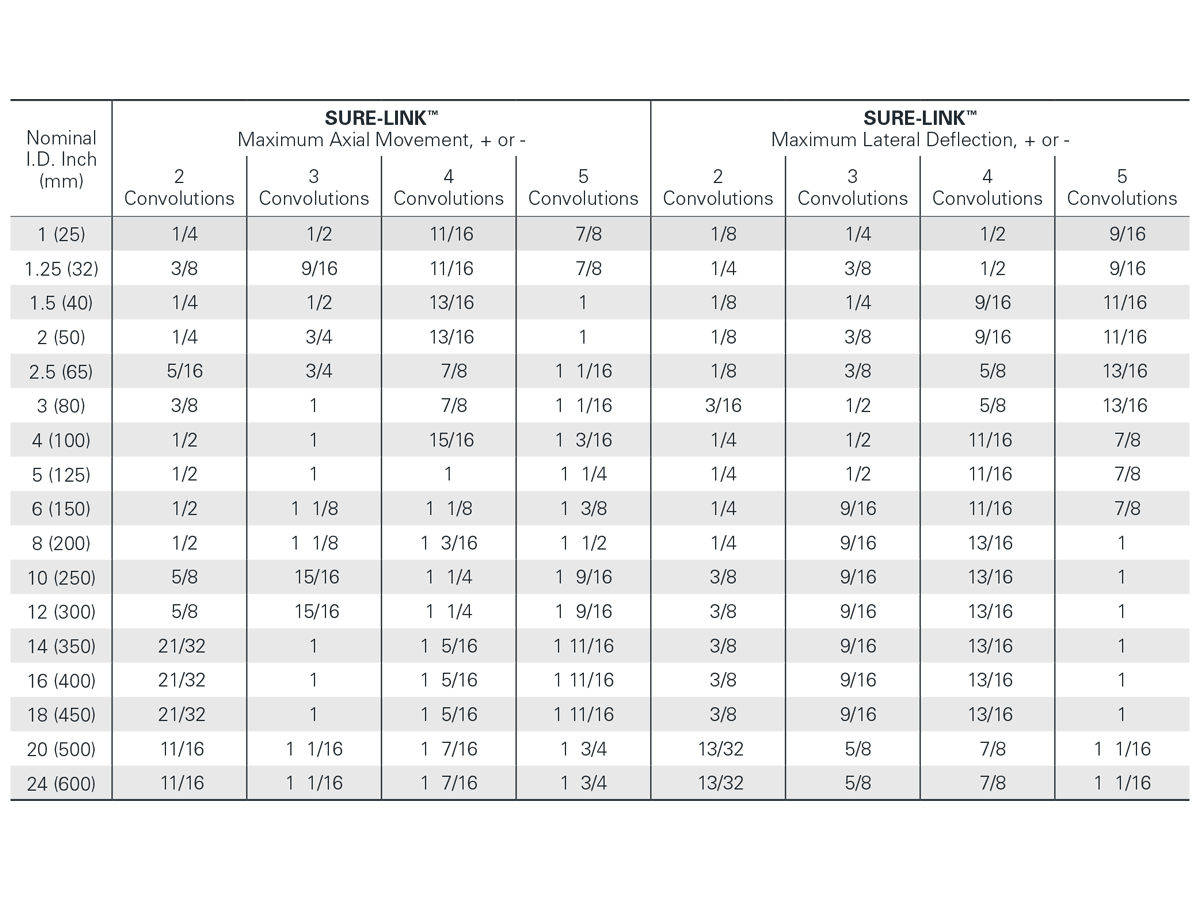

Bellows: Four or five convolution connectors designed for maximum movements and vibration eliminations.

- Pressure to 87 psig (6 bar)

- Vacuum to 17.7 In. Hg (0.6 bar) at 32°F (0°C) to No Vacuum at 212°F (100°C)

Pressure and Vacuum Rating

Garlock PTFE expansion joints and couplings have pressure ratings high enough to handle most applications. As the pipe size gets larger, Garlock increases the bellows thickness and the strength of the reinforcing rings to compensate for the change in internal forces. This permits the same high pressure.

Features and Benefits

- The convolution shape provides extra-long flex life at high temperatures

- The proprietary contour molding process ensures consistent wall thickness for improved blowout resistance

- PTFE body withstands corrosion, water, steam, and most chemicals and gases

- Preset tie rods prevent over-extension

- Available silicone-free upon request

Standard Design

Temperature: -100°F (-70°C) to 450°F (230°C)

Complete Assembly Includes:

- Fluorocarbon resin PTFE body

- Corrosion resistant plated metallic flanges

- Polyethylene-covered zinc plated restriction bolts

- Stainless steel corrosion-resistant reinforcing rings

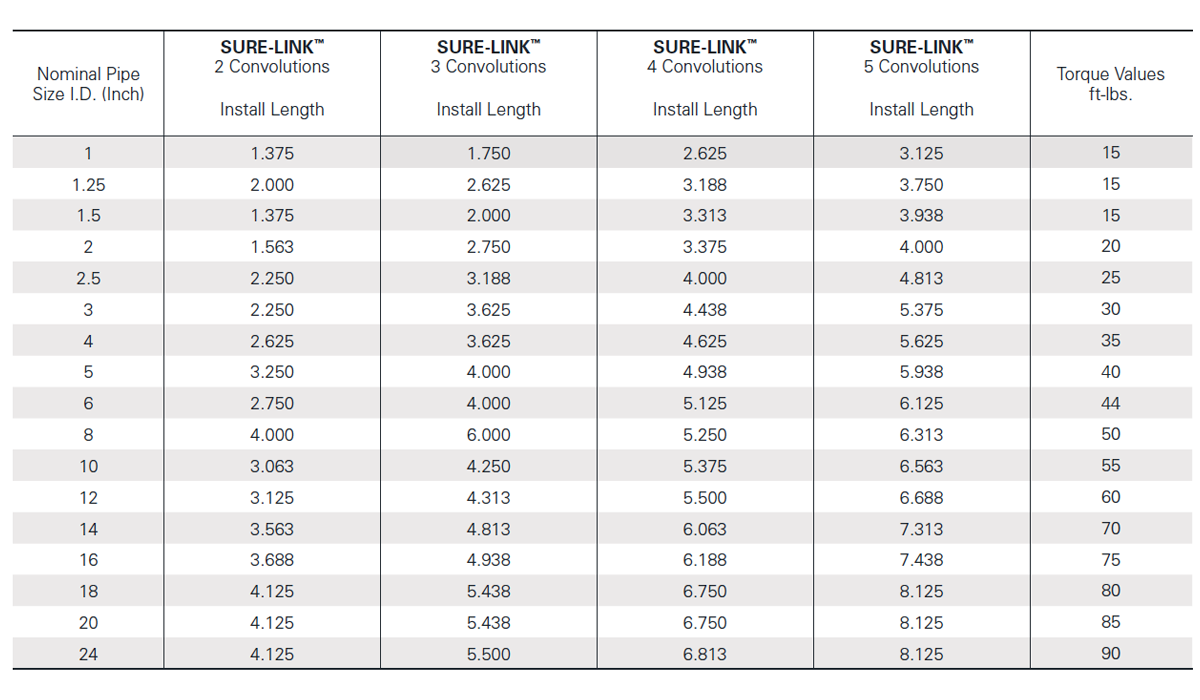

Standard sizes from 1" (25mm) through 24" (600mm) pipe I.D.

Available with 304 or 316 stainless steel flanges and tie rods upon request.

PTFE Control Units and Flanges

All PTFE joints and couplings are furnished with metallic flanges and tie rods/control units ready for immediate installation on the job site. Flanges in other alloys are available by special order.

- Flanges are protected to resist atmosphere corrosion and are tapped to ASME B16.5/B16.47 Series A Class 125/150 (standard).

- Control units are assembled with flanges to prevent joints from excessive axial elongation. They are designed to accept the static pressure thrust in the piping system.

- Tie rods are set at the factory at the maximum face-to-face working limits, with lock nuts as insurance against overextension of the expansion joint. The polyethylene covered tie rods eliminate metal-to-metal contact between the rods and flanges; the most frequent cause of noise transmission and electrolysis.