19 Fév 2018

PALMYRA, N.Y. (FEBRUARY 19, 2017) – Garlock, a leading manufacturer of high-performance fluid sealing products, has announced the launch of GYLON EPIX™. The patented next generation in PTFE gasketing features a hexagonal surface profile with superior compressibility and sealing for use in chemical processing environments.

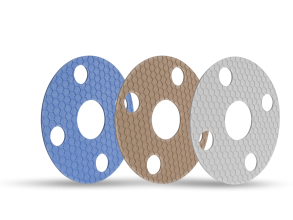

GYLON EPIX™ will be available in one universal thickness of 3/32" (2.4mm) that combines the sealing and blowout resistance of a 1/16" (1.6mm) gasket with the compressibility and conformability of a 1/8" (3.2mm) gasket. It will be available in the same three materials as traditional GYLON® products; fawn (silica filled PTFE), off-white (barium sulfate filled PTFE) and blue (aluminosilicate microsphere filled PTFE).

"The GYLON® material was the first-to-market low creep restructured PTFE and has been the industry standard for more than 50 years. With the launch of GYLON EPIX™, Garlock is redefining high performance PTFE gasketing,” said Sherwin Damdar, Product Manager – GYLON®. "GYLON EPIX™ will merge the operating advantages of 1/8” with the performance of 1/16”, changing the way gaskets are used in a wide spectrum of applications," stated Jim Drago, Principal Applications Engineer.

In metallic flanges, GYLON EPIX™ performs as well or better than existing 1/16” or 1/8” GYLON® gaskets, allowing end-users and distributors to consolidate inventory, lower the risk of using incorrect gasket thicknesses, and reduce stocking costs.

GYLON EPIX™ will provide improved compressibility and conformability, particularly for large-diameter flanges where misalignment and flatness issues typically drive end users to 1/8” thick gaskets. The hexagonal pattern also concentrates the compressive forces generated in flat-face flanges where traditional gaskets have difficulty sealing.

GYLON EPIX™ will also provide improved sealing in worn and pitted flanges. Historically users have had to resurface flanges in order to achieve an effective seal with traditional gaskets. GYLON EPIX™ breaks down that barrier with the improved conformability and reduces the need for flange resurfacing. The end result is reduced down time and lower cost of ownership for end users.

The new GYLON EPIX™ gasketing will be available February 19th, 2018.

Référence secteur:

Traitement chimique

Ingénierie, approvisionnement et construction

Alimentation et boisson

Secteur maritime

Équipements miniers

Nucléaire

Pétrole et gaz

Fabrication de l'équipement d'origine (OEM)

Pharmaceutique

Production d'énergie

Métaux de première fusion

Pâte et papier

Eau et eaux usées

Autre

Article Download: