INDUSTRY

Food & Pharma – Bulk Handling Systems

CUSTOMER

The customer is one of the world’s most experienced companies when it comes to automated handling of raw materials. The customer caters for reliable automation and logistics of raw materials in production processes in the food, pharmaceuticals, cosmetics, chemicals and plastics sectors. Main activities are in bulk handling systems for raw materials.

BACKGROUND

From engineering and the supply of individual components to the construction of complete turnkey plants, automation, installation and comprehensive after-sales service: All customer services come from a single source and they dovetail seamlessly.

Finished Product of the end customer could be food (e.g. baked products and beverages), animal food, dairy products, pharma (e.g. tablets and capsules), cosmetic (e.g. toothpaste), building chemistry (e.g. tile adhesives and plasters), basic chemistry and plastics.

CHALLENGES FACED

The performance of their existing solutions did not fulfil the requirements. The manufacturer was searching for a sealing which is free of “dead areas” and low wear as well. Further the extensive admissions of the sealing material (e.g. food grade, ADI-free, USP class VI, and many more) fit very well into their portfolio.

OPERATING CONDITIONS

1. Produced Media: food, beverage, pharmaceuticals, cosmetics, chemicals, dairy

2. Temperature: up to 40 °C

3. Pressure: up to 2 bar

4. CIP- and SIP media

SOLUTION AND BENEFIT

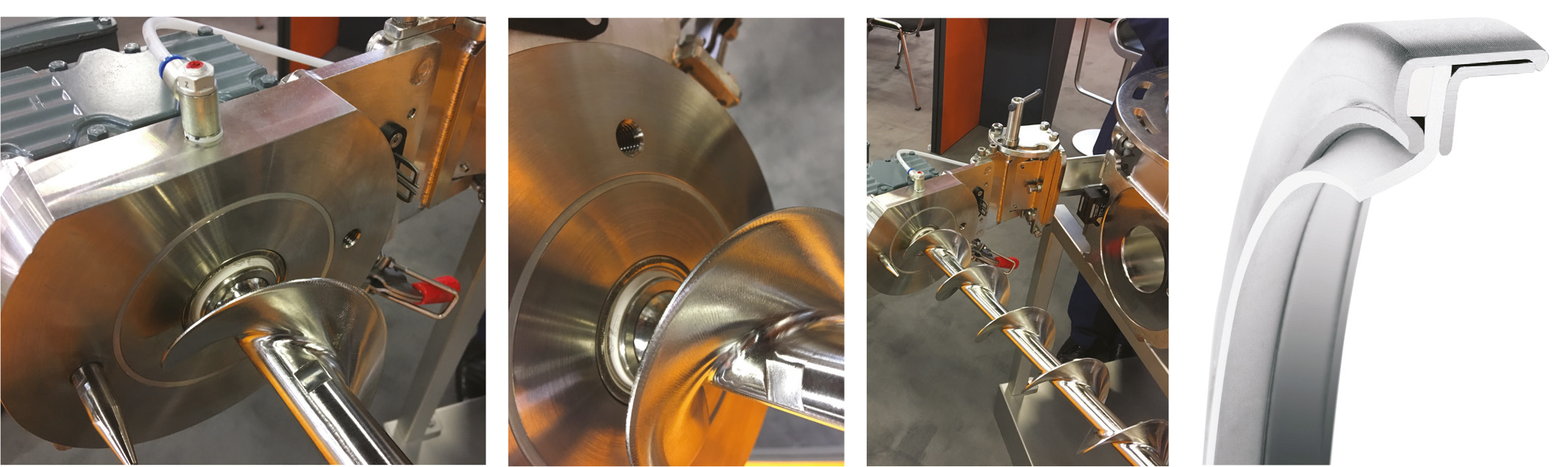

In technical discussions and reviews of the possibilities with the customer’s engineering team, Garlock supported the customer to find the best possible sealing solution. Their demands placed on hygienic connections were high. To meet the requirements of pharmaceutical and food industries, we decided to implement PS-SEAL®, Non-Standard, reverse lip in GYLON® White with static sealing GYLON® White.

Dosing systems were equipped with dosing screws with vibration support. High-precision dosing of bulk material in batch or continuous processes is now possible. 3 m/s, dry running, up to 2 bar max., up to 40 °C, media solids in food segment e.g. dextrose, FDA and EC1935 compliant, Ra 0,4mm, HRC55. Flush system in addition with air was integrated to keep down the temperature.

Because all application requirements in lifetime, food and pharma regulations and high resistance in media, temperature and abrasiveness were met, the customer set the Garlock solution into their specifications. Most sealing solutions in high performance shaft seals were replaced with the Garlock solution.