Application is similar to Size in that it relates to the equipment where the product is being used. However, unlike Size, application data may contain additional details that would not otherwise be uncovered by the basic dimensional or size information.

For example, the size of a stuffing box does not tell you if it is a valve that is actuated by hand every few days, or a pump spinning at 4000 feet per minute, but the packing products that would provide the best performance in each of these applications are completely different.

Bolts & Fasteners

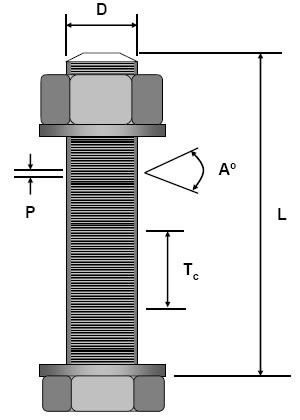

The most common method to clamp sealing devices in place is by using fasteners or bolts. There are multiple variables in a fastener that must be identified and understood in order to ensure that the sealing device receives proper loading.

First, we need to determine if the bolt or fastener threads are fine or coarse threads. Coarse threads, which are by far the most common in industry, are stronger, but not as efficient as fine threads. Therefore, a fine thread bolt requires less torque to generate the same load as a coarse thread bolt.

Secondly, flat washers can greatly improve load translation into the sealing device by creating a bearing-like surface for the nut or bolt head to slide on. Without washers, it is more likely that the nut or bolt head will bind against the contact surface of the flange, valve, or other equipment.

The third variable to consider is thread coating. Coatings are typically applied to improve fastener corrosion resistance. In addition, they can improve efficiency, thus resulting in higher compressive loads at a given torque.

The fourth variable to consider is thread lubricant. A non-lubricated bolt has less than 50% of the efficiency of a lubricated bolt. What that means is if you torque a non-lubricated bolt to 60 ft. lbs., the compressive load it generates will be approximately half of the load you would generate with the same bolt when lubricated. This concept will be demonstrated in the next few sections.

Bolt Force – Bolt #1 – No Lubricant

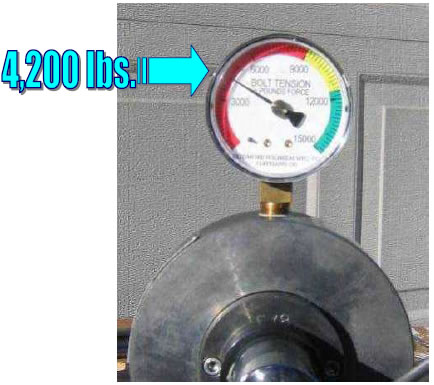

The device shown is a bolt tension device that is designed to measure load generated in pounds (lbs) when a given torque value is applied.

In this example, a 5/8” SAE Grade 5 coarse thread carbon steel bolt has been installed and torqued to 60 ft. lbs.

The resulting stress that is generated is 4200lbs.

Bolt Force – Bolt #2 – Zinc-Plated, No Lubricant

In this example, we are now using the same size and grade, but this is a zinc-plated bolt.

As you can see, in this case, the coating improves the efficiency of the bolt and the load generated. When the same torque of 60 ft. lbs. is applied, the compressive force generated increases to 5800lbs.; nearly a 30% increase in available compressive force.

Bolt Force – Bolt #3 – Zinc-plated with Lubricant

The last example is the same size and grade zinc-plated bolt, but with thread lubricant (nickel-based Never Seiz).

The compressive load generated with the same initial torque of 60 ft. lbs. is now 8400lbs! That is twice the force generated by the original carbon steel bolt, thus proving the importance of properly lubricating bolts.

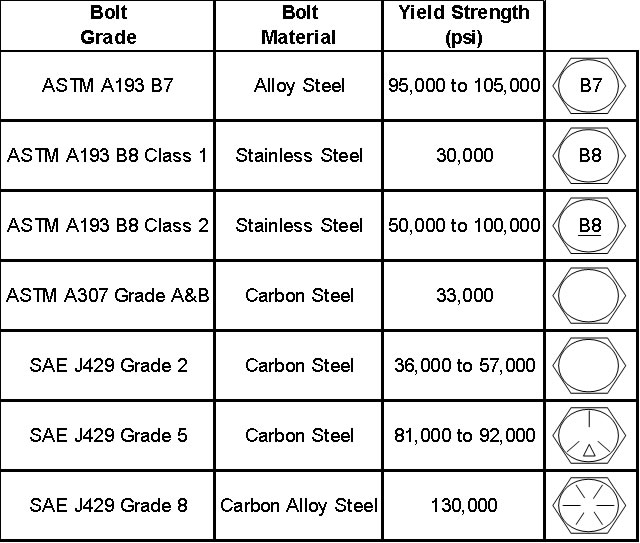

Bolt Grade

This chart shows the more common fastener grades used in industrial applications, as well as their yield strengths, which is the stress point at which a bolt becomes permanently deformed (In other words, it will not spring back to its original size when the load is removed).

Bolt grade identification is extremely important when determining proper torque values for an assembly.

For example, ASTM A193 B8 stainless steel bolts are commonly used for chemical services where corrosion resistance is required. Here, there are two different B8 bolt designations shown, however, there is a significant difference in yield strength between a class 1 (most commonly used stainless steel bolt in chemical service) and a class 2 (strain-hardened stainless steel).

Notice the only difference in how these bolts are marked is a single line under the “B8” marking, thus emphasizing the importance of properly reading the markings.

For a more comprehensive list of bolt grades, contact Garlock Applications Engineering.