Before we can properly select a sealing device, it’s important to understand the forces acting on the sealing device in the application. First, we will look at the forces in a flange assembly where a gasket is used.

Forces Acting on a Gasket

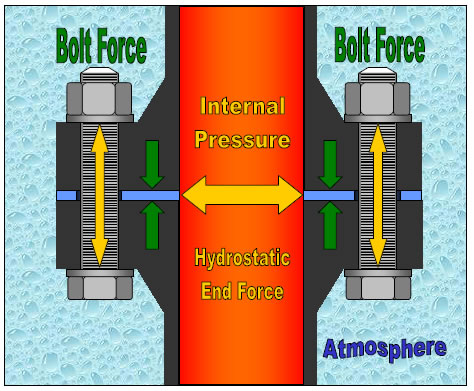

In a flange assembly, the gasket is placed between two flanges, which are then clamped together with bolts, studs, or other clamping devices.

In this example, the bolts are creating a clamping load, or bolt force, which compresses the gasket.

Once the media is introduced in the system, the internal pressure that is generated will try to push the gasket and separate the flanges. This force is called hydrostatic end force. If the hydrostatic end force exceeds the bolt force, the flanges will separate, and the gasket will leak or blow out.

The last external force we have to consider is the atmosphere. In other words, what’s going on outside the flange assembly?

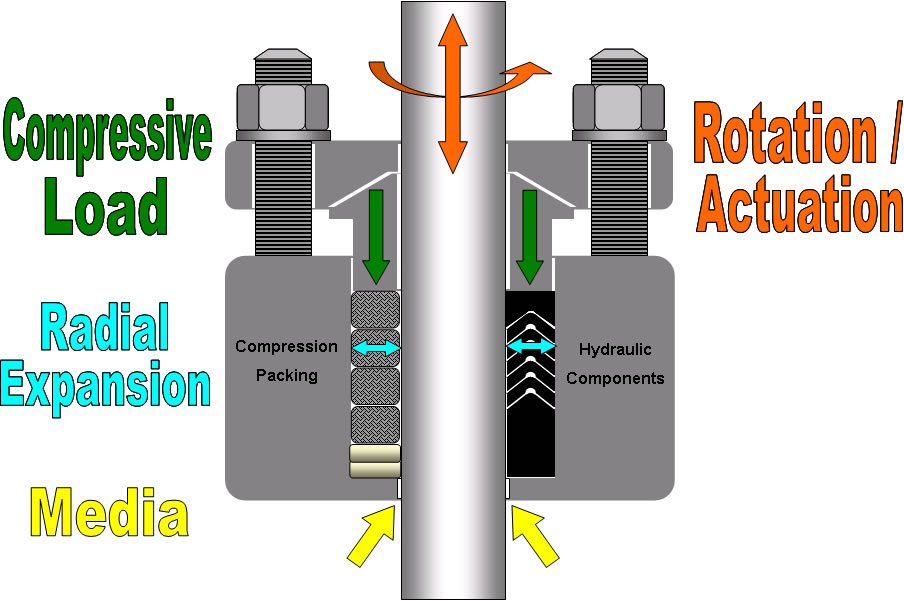

Forces Acting on a Packing or Hydraulic Assembly

In a packing or hydraulic application, compressive load is applied to the sealing components by a cylindrical device called a gland.

This compressive load causes the sealing components to expand radially, which then creates a seal between the wall of the stuffing box and the shaft, stem, rod, or ram.

When the media is introduced, it can also create additional radial expansion by way of hydrostatic load, as it tries to push the sealing components out of the stuffing box.

Lastly, shaft movement needs to be taken into consideration. How the shaft moves (rotary or reciprocating) and at what speed will directly impact the sealing device selection process.

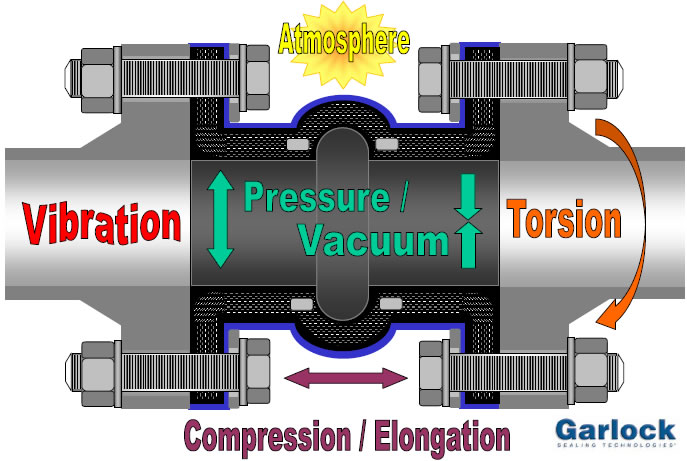

Forces Acting on an Expansion Joint

Some flange assemblies require an expansion joint, which may be used to counteract or minimize unwanted dynamic forces in the system.

These forces can be in the form of vibration, twisting or torsional movement, compression, and elongation. In addition, the expansion joint must be able to hold up to system pressure, positive or negative (vacuum).

Lastly, the exterior of the expansion joint has to be designed to withstand external atmospheric conditions, such as oil, water, and ultra-violet ray exposure.