Klozure® offers a full range of stationery seats, including all standard designs, sizes, and materials. In addition, Klozure offers non-standard shapes and sizes as well as additional materials including stainless steel, ni-resist, bronze and coated faces.

Type 01 Stationary

These o-ring stationary seats are designed to press-fit into a machined counter bore in a gland or pump housing. Before installing the o-ring, the gland counter bore and o-ring should be lubricated.

Type 02 Stationary Seat (T-Shaped)

This seat is designed to be clamped into place by the gland follower against the pump housing. It is supplied with a gasket for each side of the hard stationary. The faces are available in a wide range of materials.

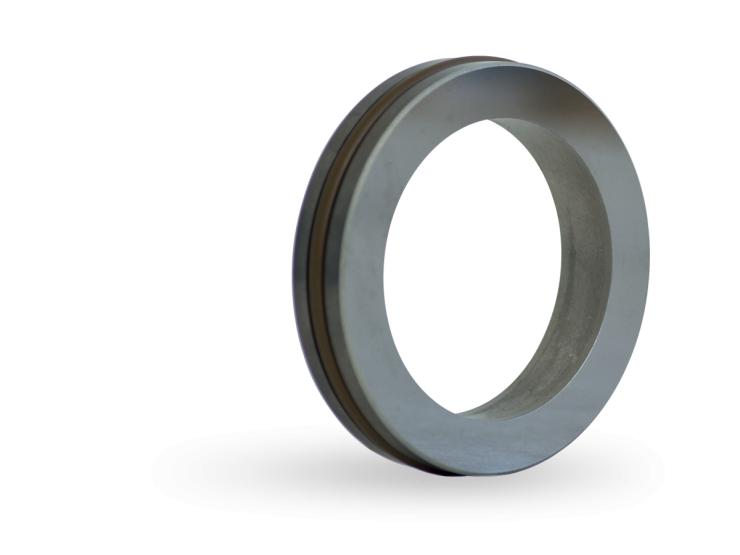

Type 04 Stationary Seat (Cup-mounted)

This seat is a cup-mounted stationary face. When installing, the cup and counter bore of the gland should be lubricated. Type 04 Seats are available in a wide range of face materials; however, the material selection for elastomers is limited to Viton and Nitrile only.

Type 08 Stationary "L" Seat

This stationary is a clamp-mounted face. It has two gaskets provided, one for each side of the face, and should be clamped between the gland follower and the equipment housing. Type 08 Seats can be provided in a wide range of materials depending on the application requirements.

Materials

Silicon Carbide

Silicon carbide is the standard for Klozure in the majority of applications. Silicon carbide offers the widest range of chemical resistance of any face material readily available today. Additionally, it is extremely hard, giving it excellent abrasion resistance. Silicon carbide also offers the highest heat transfer characteristics essential for effective sealing of high-temperature liquids. Available in three grades.

Ceramic

Ceramic has two advanragess that make it the most commonly-used seat material. it is nearly chemically inert, and it costs substantially less than other materials. Ceramic performs well in many applications. Other materials should be considered for thermally variable service, such as hydrocarbon process applications, or where elevated temperatures tend to vaporize media.

Tungsten Carbide

This is recommended for those hydrocarbon process applications destructive to ceramic materials. With good thermal shock properties, tungsten carbide also transmits heat well, minimizing media vaporization at seal faces. A hard, strong, metallic material, it easily withstands abrasive service.