Precise fit and easy installation in fugitive emissions applications

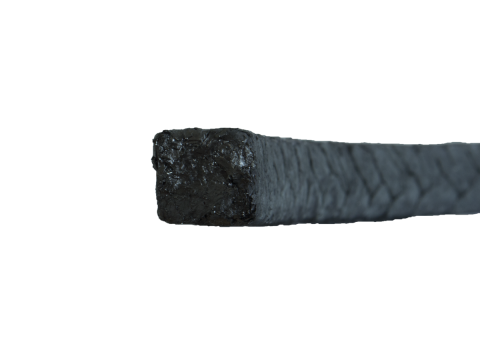

This Garlock valve stem packing product has proven itself to be an efficient and reliable solution to improve air quality by lowering VOC (volatile organic compounds) and VHAP (volatile hazardous air pollutant) emissions.

FEATURES and BENEFITS

- Forgiveness - Our ring set with patented cup and cone design, delivers higher precision fit to optimize field performance.

- Cost effectiveness - The EVSP design permits a controlled radial expansion to create an effective seal against both valve stem and bore. This engineered set can be used to seal older more worn valves. Emission compliance can be achieved without necessarily replacing valves or the maintenance expense of bringing the valves back to manufacturer’s specifications.

- Safety - This Style is fire safety tested and chemical resistant. It is well recognized in hydrocarbon and chemical processing industries as a reliable and ideally suited solution for low emission valve stem sealing.

SPECIFICATIONS

- Min. Temperature: -328°F / -200°C

- Max. Temperature: 850°F / 455°C (1200°F / 650°C Steam)

- Max. Valve Pressure: 10,000 psi / 689.5 bar

APPLICATIONS

- Hydrocarbon industry processing

- Any valve application where elimination of encrustation, chemical attack, or health hazard is required

ADDITIONAL INFORMATION

- Custom Design Capability - Choice of End Rings: Style 1303-FEP (Fugitive Emissions Service), Style 98 (General Service), Style 1303-DRY (high temperature, steam), Style G-700 or 1398 (Power Generation Special Service)