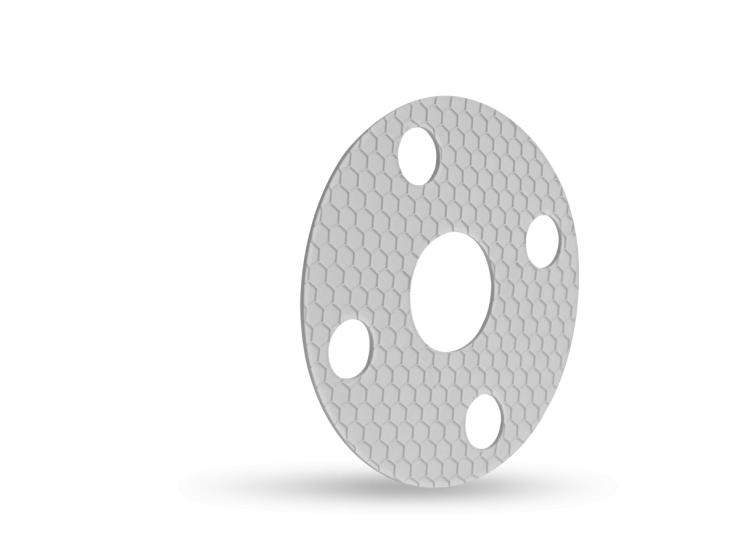

GYLON EPIX® Style 3510 is a high performance, barium sulfate filled PTFE gasketing material. GYLON EPIX® Style 3510 is designed for use where initiating and maintaining an extremely tight seal is critical; these applications include: strong caustics and moderate acids, chlorine, gases, water, steam, hydrocarbons and cryogenics.

GYLON EPIX® will provide superior functional performance by combining the traditional attributes of GYLON® with an innovative surface design. It offers a broader range of applications than traditional PTFE gaskets that are used in worn and pitted flanges. In addition, GYLON EPIX® delivers the tight sealing and load retention properties of 1/16” (1.6mm) and the conformability of 1/8” (3.2mm). The hexagonal profile provides improved compressibility and recovery. The profiled surface reduces the contact area during initial compression to concentrate the compressive force of the flange for improved sealability.

Features and Benefits

- One thickness does the job of two

- Seal performance and load retention equal of 1/16” (1.6mm)

- Compressibility and forgiveness/conformability of 1/8” (3.2mm)

- Patented hex profile creates superb sealing and ability to conform to imperfect flange surfaces

- Same material as traditional GYLON®

Specifications

- Available in sheet or cut gasket form

- PTFE with silica barium sulfate filler

- Color: Off-white

- Available in 3/32” (2.4mm)

- Seal performance and load retention of 1/16 ” (1.6mm)

- Compressibility and forgiveness/conformability of 1/8” (3.2mm)

- Temperature

- Minimum: -450°F / -268°C

- Ideal Operating Limit: 400°F / 204°C

- Maximum: See Pressure/Temperature graph

- Pressure

- Ideal Operating Limit: 750 psig / 52 bar

- Maximum: See Pressure/Temperature graph

Applications

- Strong caustics

- Moderate acids

- Chlorine

- Gases

- Monomers

- Steam

- Hydrocarbons

- Cryogenics and aluminum fluoride