The Style 204 family of spool-type expansion joints are manufactured with the industry standard narrow arch design. This style is intended to be used in dynamic conditions where both pressure and vacuum concerns are present.

Also available for high-pressure applications, Style 204 MAX has the highest pressure rating available inthe industry today.

Garlock style 204 MAX is the highest pressure rated rubber expansion joint available in the industry today. Manufactured in North America, the 204 MAX is not only a solution for applications with extreme pressure requirements, but it is also tailored for high pressure Marine and offshore applications. The design of 204 MAX has earned the ABS type approval, making it the ideal solution for single point mooring stations requiring a 4:1 safety factor. The 204 MAX has also been extremely successful in many other applications, and has been specified in high pressure applications that pump water to copper mines.

The 204 MAX can be configured to meet specific customer needs and is compatible with virtually any media. The ABS type approval provides cost savings to end users by eliminating destructive testing during the requisition process.

View Expansion Joint Style 204 3D Model/Rendering

FEATURES and BENEFITS

- Fully laboratory and field tested for long life and exceptional reliability

- High pressure and vacuum resistance offer increased safety and ensure suitability for a wide range of applications

- Single and multi-arch designs are available for a range of movement capabilities

- Concentric and eccentric reducing configurations can be provided to join piping of unequal diameters

- Available in a variety of elastomers and fabric combinations to meet the varied demands of temperature, pressure, and media

Specifications

- Size:

> Min. Inner Diameter: 0.5 in / 13 mm

> Max. Inner Diameter: 120 in / 3000 mm

- Temperature:

> Max temperature rating is based on the lowest temperature of the material selected

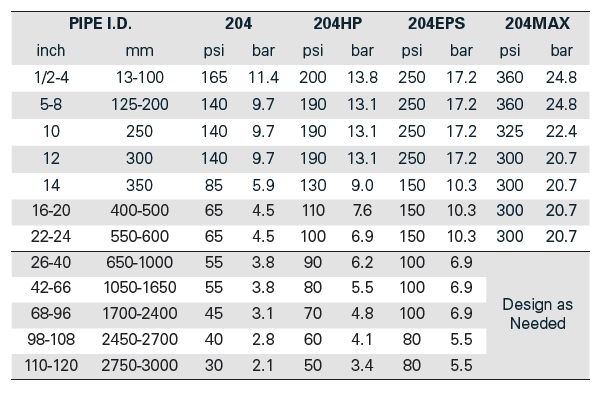

- Pressure and Vacuum Rating:

- Vacuum Rating (29.9 In. Hg (750mm Hg.)

> Full vacuum rating for all sizes and face to face - > Style 204EVS available for continuous full vacuum service

CERTIFICATIONS

- Canadian Registration Number (CRN) - All Provinces - 204HP (1/2" - 96" ID)

- 10CFR50 Appendix B - 204, 204HP, 204EPS

- ABS Type Approval - 204HP (1/2" - 96" ID), 204MAX (2”- 24” ID)

- ASTM F-1123 Compliant - 204HP, 204MAX on request

APPLICATIONS

- Rigid piping systems

- Compensate for axial, lateral, torsional, and angular movement

- Compensate for misalignment

LINER MATERIALS

For more info on these materials click here.

- ABRA-LINE™: +180°F (+80°C)

- ABRA-SHIELD®: +300°F (+150°C)

- Natural Rubber: +180°F (+80°C)

- GUARDIAN® FEP: +400°F (+205°C)

- FKM (Fluoroelastomer): +400°F (+205°C)

- CSM: +250°F (+120°C)

- SURE-TEC™ FDA/NSF-61 EPDM +250°F (+120°C)

- EPDM/FDA EPDM: +300°F (+150°C)

- HNBR (Hydrogenated Nitrile): +300°F (+150°C)

- Nitrile/DETECTOMER® FDA Nitrile: +250°F (+120°C)

- Chlorobutyl (Standard): +250°F (+120°C)

- Neoprene/FDA Neoprene: +250°F (+120°C)

ADDITIONAL INFORMATION

Standard Design

Tube

- Chlorobutyl resists cracking due to high temperatures, weathering, oxidation, and chemicals

- Abrupt arch configuration provides maximum movement and maximum pressure and vacuum resistance

- Seamless tube creates a positive flange seal without gaskets

Body

- Chlorobutyl/polyester construction with welded, treated metal body rings for dimensional stability

Cover

- A homogeneous layer of chlorobutyl fully extends to the outside edge of the flange

- A durable exterior coating futher protects the expansion joint from the effects of weathering and oxidation

Optional Configurations

- Multiple arch for higher movements

- Filled arch to eliminate media buildup

- Oversized arch for higher movements

- Concentric and eccentric tapers to connect piping of unequal diameter

- Custom Drilling - ANSI, DIN, AWWA, BS, JIS, and special drilling patterns available on request

- Extended face-to-face

- Accommodate misalignment: lateral, angular, and torsional offsets