INDUSTRY

Mechanical Engineering

CUSTOMER

Our client offers milling solutions designed for the most demanding production environments, such as the power generation, automotive, aerospace and railway industries.

BACKGROUND

By offering the widest range of milling solutions on the market, including bed machines, gantry machines, floor type machines and machines with a T-shaped configuration, the demands are high.

CHALLENGES FACED

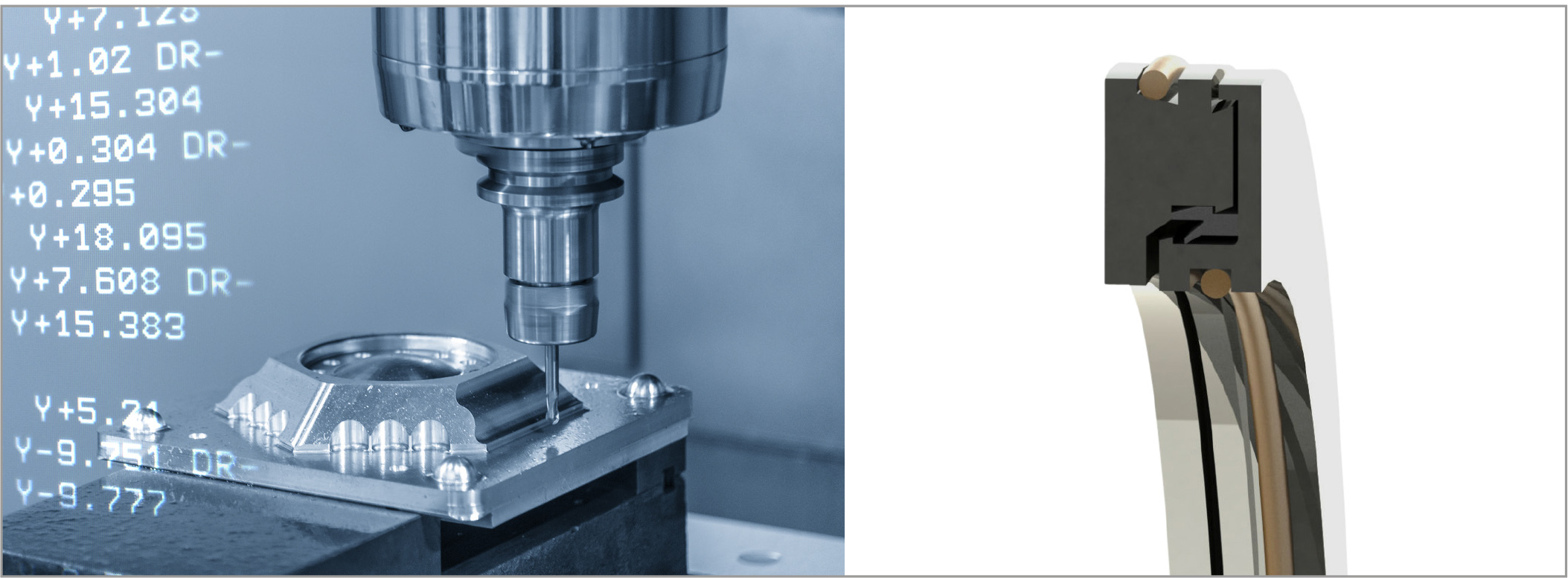

The customer introduced new milling heads in their 5-axis machines and were looking for a specially designed isolator.

As it was a 5-axis machine, orientation of the head was constantly changing. Additionally, it was critical that the isolator does not increase temperature in the bearing chamber as this could impact in the performance of the bearings.

OPERATING CONDITIONS

Speed: 6000 rpm / 80mm diameter shaft (25 m/s)

SOLUTION AND BENEFIT

GUARDIAN® has been selected for the ability to provide a specially designed isolator, adapted to the customer’s new heads and for its great performance after intensive testing.

GUARDIAN® protects a high speed 6000 rpm / 80mm diameter shaft (25 m/s) of their new milling heads, avoiding turbulent air-oil mist flow to get into the grease-lubricated bearings.

GUARDIAN® mastered the requirements of the 5-axis machines and their heads and did not increase temperature in the bearing chamber.

Prototypes were successfully tested in their test heads for several months. The customer has specified GUARDIAN® for their new head design, which is being introduced in all their new machines.

Classification du fichier:

Études de cas