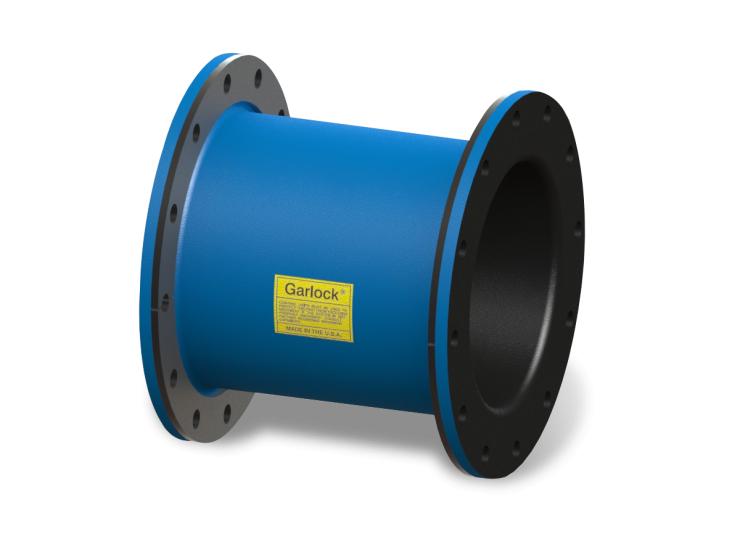

Expansion joint that conforms to U.S. Navy specifications

Garlock 7250 FLEXO-MATIC® rubber connectors are composed of three basic elements: the tube, the body (carcass), and the cover. Designed to absorb noise and vibration in air-conditioning, heating, and industrial piping systems, Style 7250 FLEXO-MATIC® expansion joints accommodate a wide range of temperatures, pressures, and piping sizes.

Regional Availability Restrictions:

Not available in Europe

FEATURES and BENEFITS

- Eliminates noise at its source. Garlock FLEXO-MATIC® rubber connectors are designed to absorb equipment noise before it is transmitted through piping systems.

- Reduces vibration and lengthens equipment life because high-frequency vibrations are virtually eliminated.

- Expansion, contraction, and misalignment are all compensated for with FLEXO-MATIC® connectors.

- Absorbs water hammer, vibrations of the fluid itself, by FLEXO-MATIC® design.

- No electrolytic action, since there is no metal-to-metal contact between connectors and metal pipe.

SPECIFICATIONS

- Temperatures to 400°F / 204°C

- Pressures to 150psi

- Standard pipe sizes from 2in through 12in

APPLICATIONS

- Air conditioning

- Heating

- Industrial piping

LINER MATERIALS

For more info on these materials click here.

- ABRA-LINE™: +180°F (+80°C)

- ABRA-SHIELD®: +300°F (+150°C)

- Natural Rubber: +180°F (+80°C)

- GUARDIAN® FEP: +400°F (+205°C)

- FKM (Fluoroelastomer): +400°F (+205°C)

- CSM: +250°F (+120°C)

- SURE-TEC™ FDA/NSF-61 EPDM +250°F (+120°C)

- EPDM/FDA EPDM: +300°F (+150°C)

- HNBR (Hydrogenated Nitrile): +300°F (+150°C)

- Nitrile/DETECTOMER® FDA Nitrile: +250°F (+120°C)

- Chlorobutyl (Standard): +250°F (+120°C)

- Neoprene/FDA Neoprene: +250°F (+120°C)

ADDITIONAL INFO

The construction features of the 7250 FLEXO-MATIC® is as follows:

- The Tube–A protective, leakproof lining made of a synthetic rubber which may vary depending on the service. Garlock's standard tube is specially compounded to resist the hot and cold water found in air conditioning and heating systems. The seamless tube extends through the bore to the outer edge of the flange. Its purpose is to eliminate the possibility of the fluid penetrating the carcass and weakening the fabric.

- The Body or Carcass–Consists of fabric and rubber, reinforced with metal.

- A. Fabric Reinforcement – Cotton duck, Dacron®, or other suitable fabrics impregnated with an elastomer are wrapped and applied to provide the flexibility and support required between the tube and cover.

- B. Metal Reinforcement – Helical-wound steel reinforcement wire is firmly embedded in the carcass to provide resistance to both vacuum and pressure. Extra strength is provided in the critical flange corner area to provide positive flange sealing at 150psi for Style 7250.

- The Cover – A homogeneous layer of synthetic rubber to protect the carcass from corrosive attack or mechanical damage, the rugged cover withstands aging and weathering for a long, trouble-free life.

- Flanges – Garlock expansion joints are furnished with USA Standard 125/150lb. or 250lb. drilling. Navy or other special drilling and beaded flanges are also available on request.

- Steel Retaining Rings – Installed directly against the inner face of each flange, they provide a metal surface which equally distributes the bolt pressure around the flange. The bolts cannot damage the flange and yet sufficient pressure can be applied to effect a seal without using gaskets. Retaining rings are normally furnished with a corrosion-resistant coating, but galvanized or stainless steel retaining rings are also available on request.

Dacron is a registered trademark of E.I du Pont Nemours and Company.