INDUSTRY

Food Processing – Fried Snack Foods

CUSTOMER

A major diversified food & beverage manufacturer, with facilities located in all regions across the globe.

BACKGROUND

The customer had persistent problems when sealing hot oil applications on its bulk snack food fryers across several production sites. Build-up of polymerised vegetable oil on the flanges caused unsightly mess, maintenance complications, financial implications, and posed a significant fire risk.

CHALLENGES FACED

As well as ensuring that the sealing material was compliant to FDA and EN1935 standards, the challenge was to ensure that the gaskets would perform well under the difficult conditions presented by the high oil temperatures. Additionally, because the production line was also subject to regular and aggressive cleaning cycles, the gasket material was required to be compatible with other aggressive chemicals across a broad pH range.

OPERATING CONDITIONS

- Media: Edible Oil (with 5-10% caustic cleaning)

- Size: 4” Flange (rated 150lb)

- Temperature: 338º - 392 º F (170º - 200ºC)

- Pressure: 2.5 bar

SOLUTION AND BENEFITS

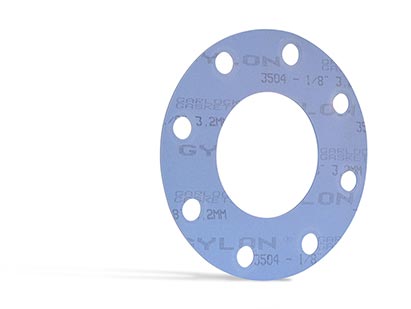

Through in-depth discussion and collaboration with the customer’s engineering team, it was determined that the best solution was to implement GYLON® Style 3504 gaskets in the application. This would support the required level of compliance to industry standards, and the modified PTFE structure would provide compatibility to both chemical and mechanical demands of the process.

Additionally, and in order to ensure that ongoing usage of this product remained both efficient and safe, a full training programme was provided which delivered installation training and trouble-shooting advice. The outcome is that the customer has now implemented GYLON® Style 3504 across multiple facilities and is enjoying the benefits of a more effective and safer sealing product.